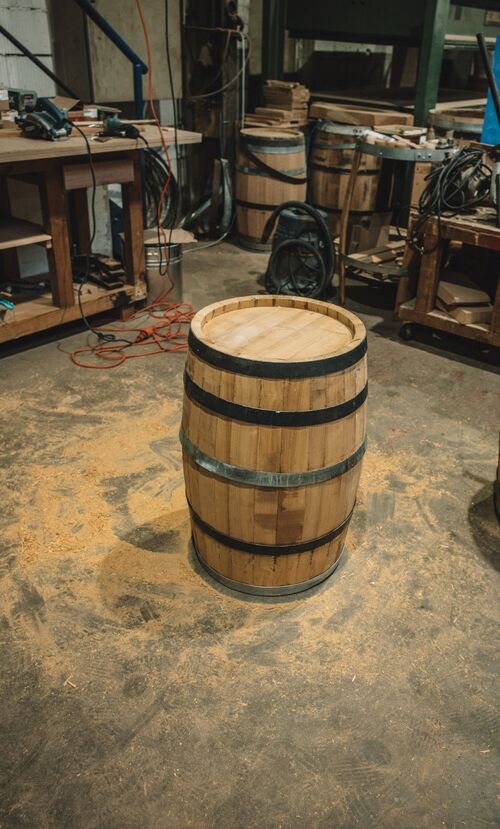

Masters of Wood

A visit to Wilhelm Eder GmbH, a barrel manufacturer in Bad Dürkheim

This chapter in our never-ending search for unique aromas and new sensory experiments led us straight to the Palatinate (southwest Germany), where wooden barrels are still made by hand for the maturation and refinement of distillates. We even got the chance to watch a cooper go about his work.

Once it is cut, the wood is stored outside to dry slowly before being placed in a vacuum dryer at a constant level of humidity (around 14%).

After that, the staves are cut down to the desired length and made a bit thinner in the middle, which already gives them a slight curve. The sides of the staves are also treated with care, as anspitzen (or "narrowing") is delicate work. As a result, the wood is always somewhat wider in the middle than at the ends, which is what gives barrels their convex shape. The next step involves finding the sides of the staves that fit together best to ensure that the seams line up precisely later on. Once the staves are arranged in the proper order, the cooper makes a mark at the exact midpoint of each one.

Once the staves are inserted into a hoop, the cooper can quickly tell whether his careful work has done the job. If not, the staves will fail to support one another. Additional hoops then provide for further stability. This too is a matter of millimetres: All the staves have to line up with the same height marking made in a previous step, which involves tapping them into place. When all the staves fit together as they should, the head hoop is hammered onto the top of the barrel.

Toasting the wood of a barrel has a significant effect on the taste of its eventual contents. When a barrel is placed over a smouldering fire, the macromolecules in the wood dissipate and are replaced by even smaller chemical bonds that serve to enhance flavour. The process also breaks down undesirable aroma agents and resinous substances on the inside of the barrel.

Meanwhile, the heat applied makes the wood flexible enough to be bent into a barrel shape - with the help of steel cables, of course. A cable is wound around the splayed staves and slowly drawn tighter using a vice. After all the gaps have been closed, the cooper replaces the cable with two more hoops. All the while, he has to keep making sure that all the staves fit properly into the hoops.

Once the barrel is cool and dry, the cooper brings out two different types of special milling tools. One is for bevelling the edges of the barrel, and the other is for carving a groove (or croze, as it's also known) into which the head of the barrel will be inserted.

Reeds are placed between the boards of the head, which are connected by dowels. The cooper is then ready to saw the head into a round shape and fit it into the barrel.